Indicators on Quick Attach Attachments You Need To

Since this business could be more hazardous than others due to operating together with hot metal and heavy duty machinery, every welder and sheet metal fabricator should be aware of the security guidelines in their various stores. To help prevent injury, every tradesperson needs to own or be provided (at least) the following:

To help develop a secure work environment, every trades shop should have strict equipment storage policies (whether automatic or handheld ), and every apprentice has to be trained prior to using machinery by themselves. All tools must be completely and frequently inspected for any damage.

When it comes to welding and fabrication, both careers are important. This transaction is beneficial to transportation and automotive, from home and construction for each and each industry.

What Does John Deere Attachments Do?

At Kaempf and Harriswe deliver powerful and efficient fabrication, installation, and design-build projects using stainless steel, galvanized steel, black iron steel, and aluminum. It is possible to find out more about welding alloy metal fabrication and more.

Itd be a downright shame as it came in case your gear didnt work, which explains precisely the reason the reason we test-run everything.

BARN is happy to have the ability to provide courses in Metal Machining, Welding and Sheet Metal. We offer Knife and Forging Making classes offsite in cooperation with Alchemy Industrial Arts. Our shops are staffed with instructors having jointly many years of experience. Our objective is that you enjoy learning about processes and the machines which will allow you to create metal objects of attractiveness and usefulness. .

An Unbiased View of Attachments For Bobcat

Come and take and get you comfortable with our machinery and processes. With enough experience, you can join our spacious studios to perform on your own projects with qualified folks available to provide assist.

The machine tools at the Barn Machining Studio allow you to cut metal or plastic to create objects of your own design, such as spinning tops, hammers, boat parts, automotive parts and intricate mechanisms such as Stirling engines or anything you imagine. In case you cant find it in the hardware shop, it is possible to make it in BARN. .

The welding studio is where to cut and join aluminum and steel to create functional as well as decorative items. The plasma cutting machines enable you to hand-cut sheet steel to make artwork pieces signs and parts. The CNC plasma cutter allows you to select from a computer-based design.

Quick Attach Attachments Fundamentals Explained

Light bending and hammering can be accomplished with browse around here the Oxy Acetylene rigs. .

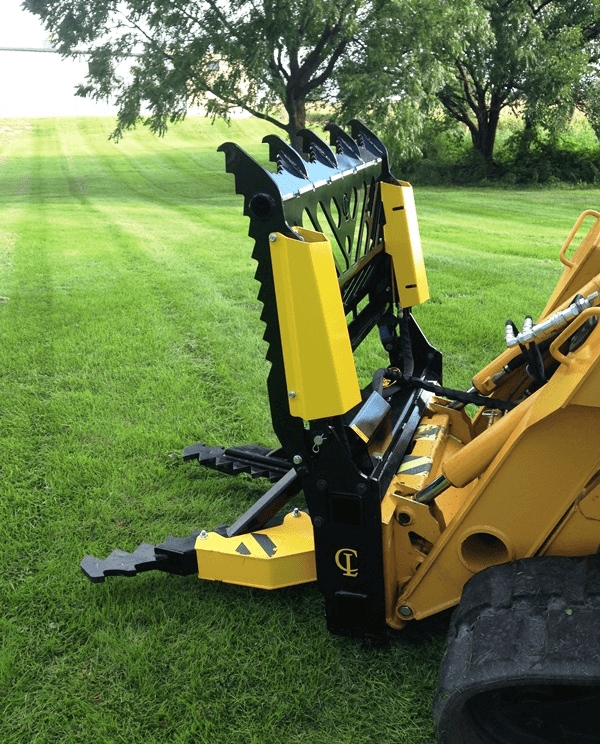

C L Fabrication

420 S 8th St, Clarinda, IA 51632, USA

(712) 542-5500

The Jack Archer Sheet Metal Studio is where to generate all sorts of shapes from sheet metal. Stars, cookie cutters, planters, boxes, kinetic sculptures or what ever you envision that could come from bending and cutting thin metal.

The Ultimate Guide To Tree Puller For Skid Steer

Forging is the process of heating to the stage it softens so that it may be shaped by hammering, bending or other methods. Knife may be done this way. BARN and Alchemy Industrial Arts offer classes through BARN that are held in Alchemy for Blacksmithing and Conventional Knife Making.

Prerequisite: People wanting to use Open Studio Time at Alchemy Industrial Arts must have taken at least a forging or knife creating course at Alchemy so they are familiar with the safety protocols, processes and clean up procedures. To participate in Alchemy Open Studio Time, BARN members should enroll and pay a 10 studio use fee.

.

Bobcat Forks Things To Know Before You Buy

Metal Fabrication Studio Phones: 206-842-4475 Machine Shop: ext. 207 Welding & Sheet Metal Shop: ext. 208

Access is available to Metal Fabrication members and requires member authorization to access content. Request access here.

Not known Facts About Tree Puller Attachment For Skid Steer

SON Metal Fab has been a custom made sheet metal manufacturing company comprising 30 decades of business experience. We are outfitted to satisfy the specific needs of the wide array of clients by metal fabrication welding jobs combining machining, welding and sheet metal fabrication.

The 10-Minute Rule for Quick Attach Attachments

Sheet metal browse around here manufacturing is a procedure by which metal components are cut and bent from a roster of inventory material that's generally less than 0.25 thick.

Metal-Fab has established itself as the leader in the residential, commercial, and industrial ventilation industry. Our beliefs are simple Offer our customers the absolute best products and deliver these products faster than anyone in the business.